Turbomachinery Filter Solutions

Turbomachinery Filter Solutions

BACKGROUND

The operation of a gas turbine, by its basic design, requires it to ingest large quantities of air. For example, a 30,000 hp Solar Turbine Titan 250 gas turbine has a reported exhaust flow of 541,590 lb/hr (at 70° F and 14.69 psia and assuming inlet mass flow is 2% less than exhaust flow the volumetric flow is 118,214 acfm). Even in relatively clean environments, a gas turbine may ingest hundreds of pounds of foreign matter each year of various sizes. For example, 1 ppm of particles in the ambient air is equivalent to 12.7 lbs of that particulate entering a gas turbine without filtration each day at a mass flow rate of 530,758 lb/hr. Also, the more advanced the turbine design, the more sensitive it is to the quality of the air ingested. Filtration is applied to the inlet air to provide protection against the effects of contaminated air. Different types of contaminants in the air from the world-wide variety of environments can cause several types of problems that negatively impact the reliability, availability, and time between overhauls of gas turbine internal components. The foremost purpose of inlet filtration is to clean the air to meet the operational goals of the machine and, secondarily, to maintain its filtration efficiency. Specific filtration designs protect against particles of various sizes and composition.

Effects of Air Filter

Air filter for Gas Turbine Air Inlet System is to prevent dust.

Dust Particles can cause:

1.Turbine blade cooling passage plugging leads to low efficiency of work and offset of surge curve.

2. Fouling, Particle fusion, and corrosion (hot and cold).

3. Foreign object damage and Erosion.

WHY NEED PRE-FILTER?

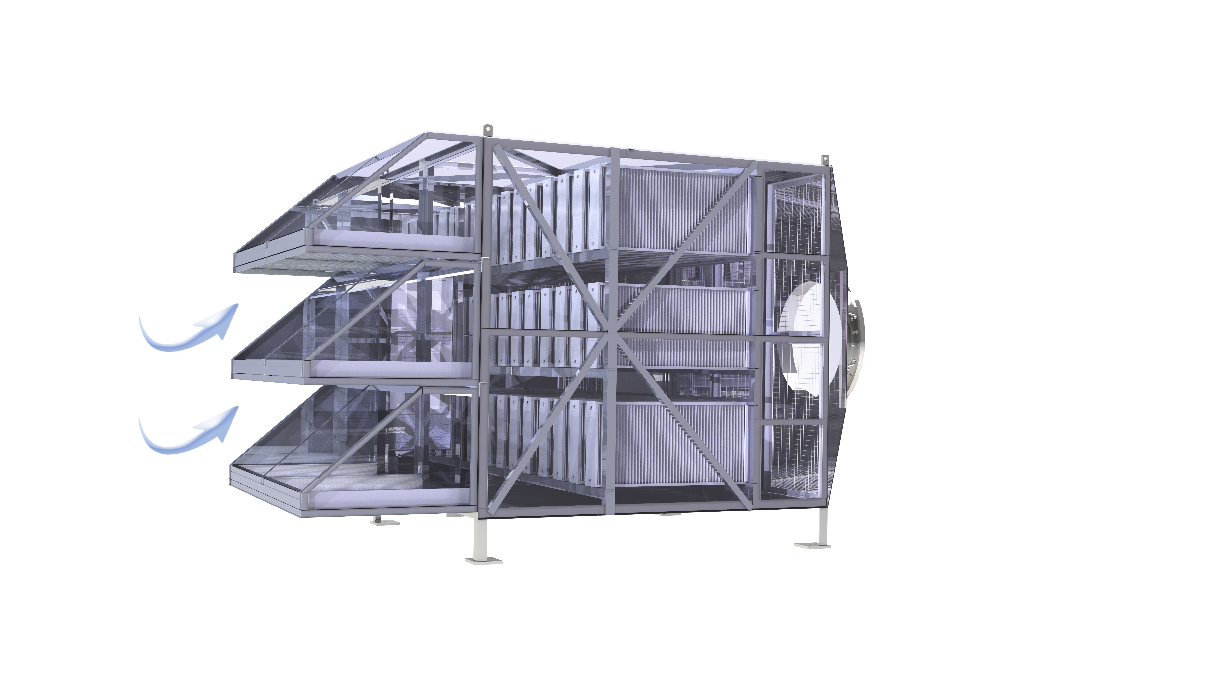

Most gas turbines are with single-stage filtration (although some of them are with sheet filter, but its media area is too small). It is hard to meet the need of safe, steady and long-term operation.

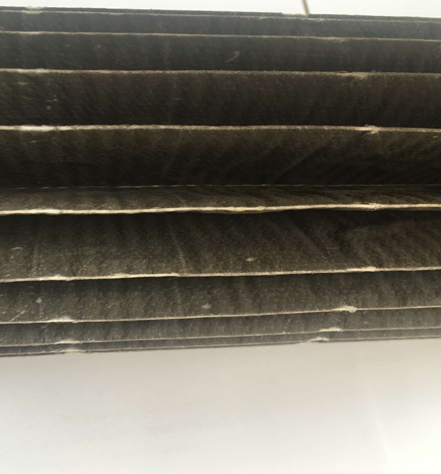

Based on current filtration system, we add the pre-filter in front of the final filter. It is mainly used to remove the particles which is bigger than 1μm. The pre-filter can help get rid of the 18.51% dusts, accounted for 97.98% of the total weight. It will greatly reduce the stress of fine filter and extend the life cycle of the filter.

Advantages of Adding Pre-Filter:

1.Under the condition of high humidity and heavy rain, pre-filter can take use of its cohesion to remove most amount of the water.

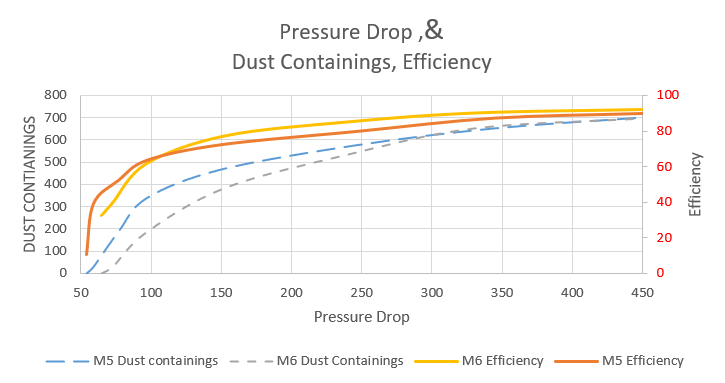

2.Pleated panel filter or pocket filter have more flirtation area. It can help pressure drop of fine filter rises up gently and ensures operation of gas turbine steady for a long time.

3.Pre-filter is with lower pressure drop; it can help introduced the air into the gas turbine intake house.

4.It can realize online replacement of the filter to deal with certain emergency.

A turbo compressor is a power compressor with a high-speed rotating impeller. It relies on the interaction force between the rotating impeller and the airflow to increase the gas pressure, at the same time accelerate the airflow to obtain kinetic energy, and then the airflow decelerates in the diffuser to convert the kinetic energy into pressure energy to further increase pressure. The gas flow is continuous during compression. The turbo compressor is developed on the basis of the fan. It is widely used in various processes to transport air and various gases and increase their pressure.

They play an important role in many industrial productions used to improve our daily life. Our compressor air intake system provides a reliable guarantee for the power output of these equipment.

The dust and pollutants in the air seriously affect the efficiency and service life of these high-speed equipment. Dust and contaminants can cause wore, erosion and scaling inside the equipment. In this field, we have more than 20 years of experience. Our air intake system has excellent filtration effect, long service life and optimal energy consumption. It protects your expensive equipment, improves production efficiency, and ensures turbine equipment keep in the high efficiency and reliable and long-term operation.

Air Filter Selections

We developed various media for different environment, like oceans, deserts, tropical and so on.

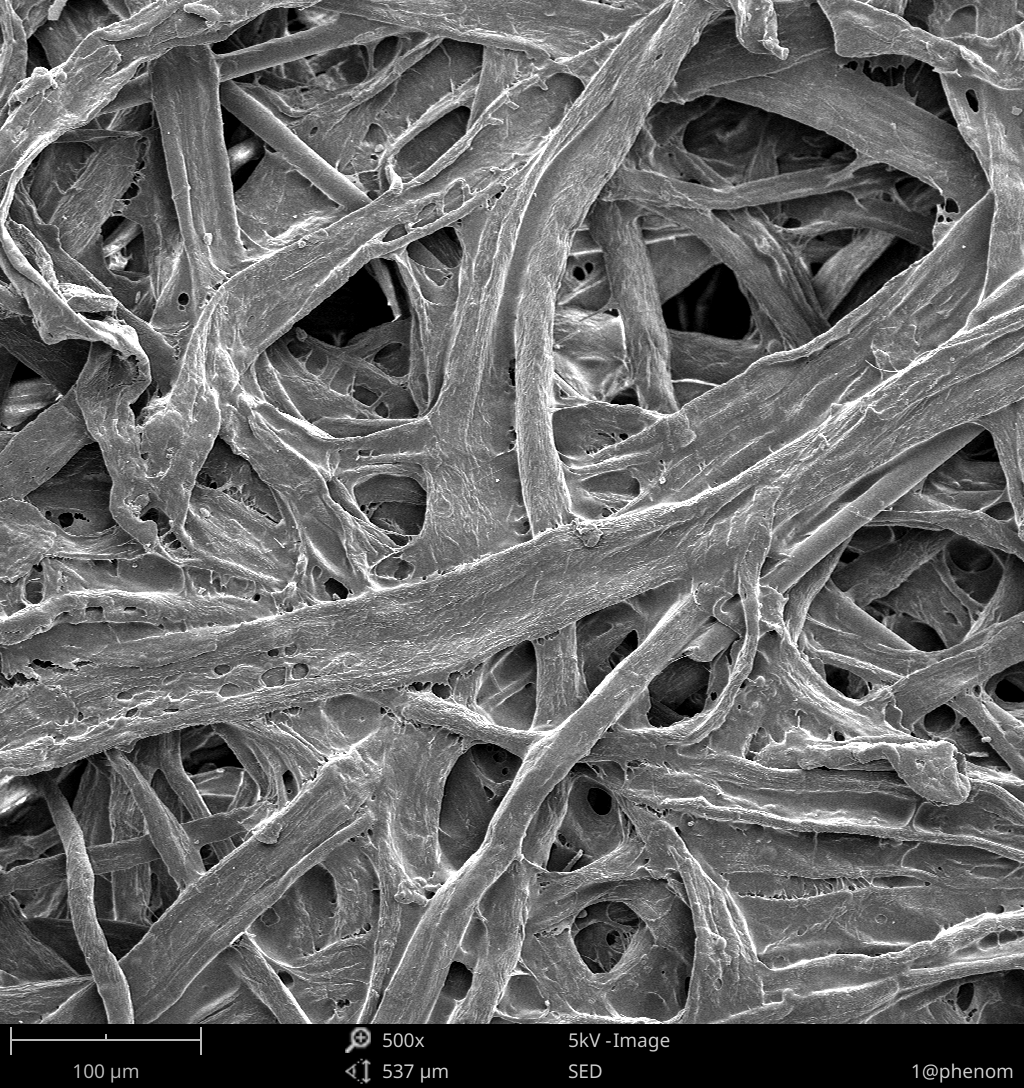

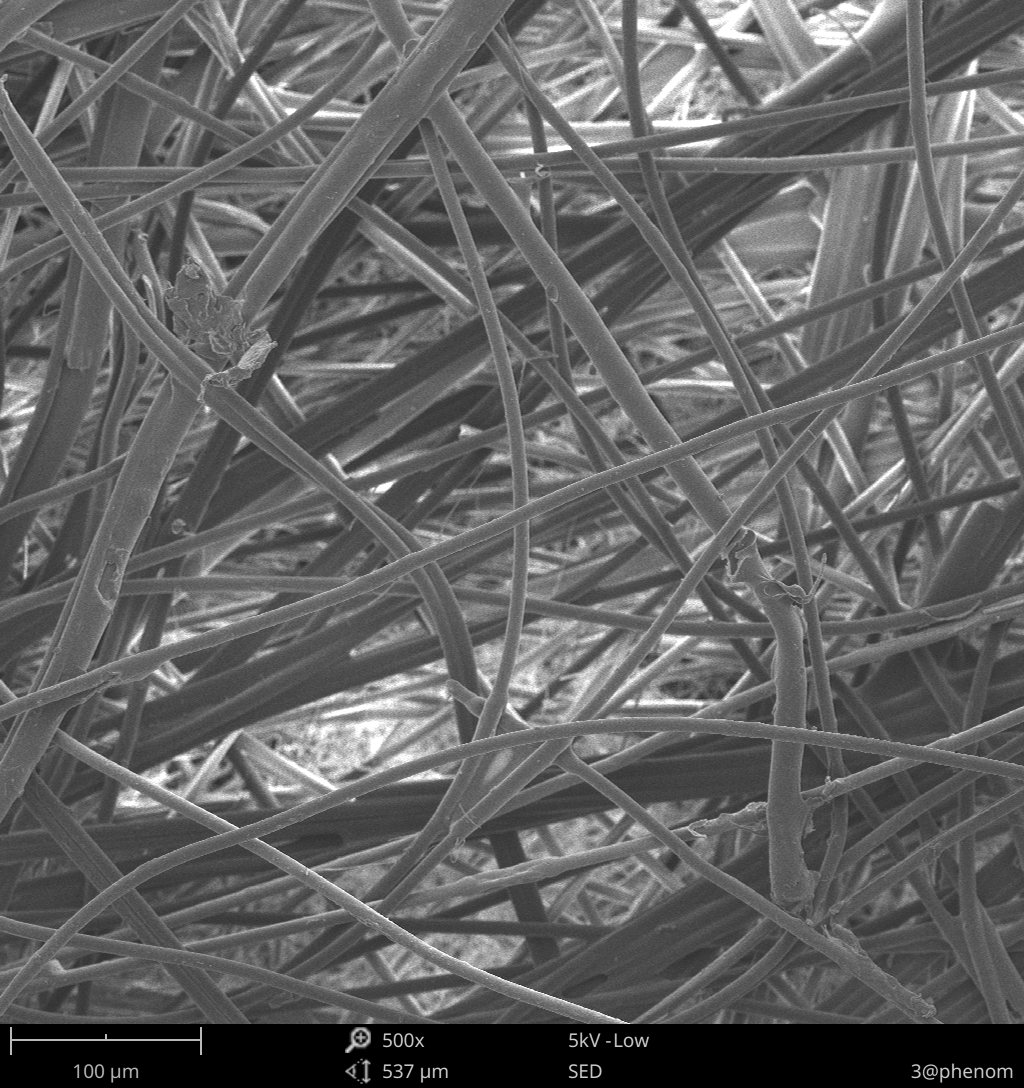

Cellulose paper

synthetic fiber

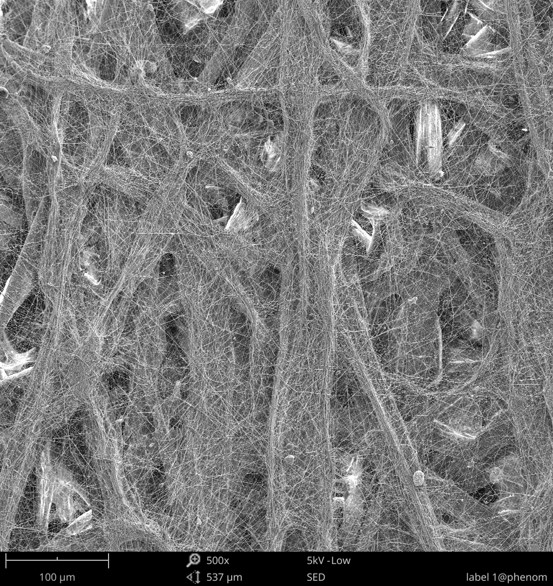

nano-fiber

And we developed HE@Pleat pleat technology, separated by hot melt to keep the pleats the perfect shape. Besides, there are similar space between pleats so that it forms a passage for contact media with air. While it ensures the filtration efficiency, the filter obtains the minimum pressure drop. Additionally, it also improved the hydrophobic performance of the filter.